3D Printed Core Tubes

A mining company that was engaged exploratory drilling had a large number of cores that needed to be cut. The core saw they used required that the cores be loaded into a steel tube, that held the cores in place while they were being cut. They tubes weighed 10lbs when empty and where causing fatigue in the employees having to constantly handle them during a long shift.

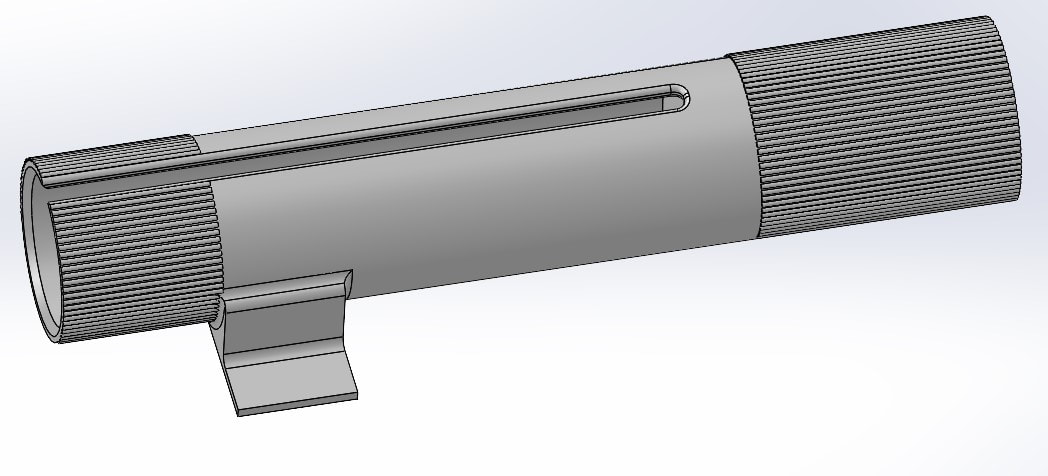

Millson Design Solutions designed and printed a core tube made out of PLA plastic that lowered the weight of the tube to 1lbs, so that the tubes when filled with cores weighed the same, as the steel tubes did when they were empty. Additional other features, such as ribbing to enhance the grip of the tubes were added. Thanks to the automated process of 3d printing manufacturing, the tubes cost less than 1/3 of steel tube price.

Additional as there is no specific tooling required in 3d print manufacturing, the design could be modified and updated with each batch that was printed to optimize their performance. They could also be marked, identifying it to each saw and adding company logos.

Millson Design Solutions designed and printed a core tube made out of PLA plastic that lowered the weight of the tube to 1lbs, so that the tubes when filled with cores weighed the same, as the steel tubes did when they were empty. Additional other features, such as ribbing to enhance the grip of the tubes were added. Thanks to the automated process of 3d printing manufacturing, the tubes cost less than 1/3 of steel tube price.

Additional as there is no specific tooling required in 3d print manufacturing, the design could be modified and updated with each batch that was printed to optimize their performance. They could also be marked, identifying it to each saw and adding company logos.