Grabber Finger Replacement

A greenhouse operator was experiencing difficulties with the grabber fingers on their pick and place transplanting machine. The stainless steel fingers would occasionally get bent over the course of normal operation, and would require replacement. Unfortunately, customer support for the machine, which was manufactured overseas, was difficult to obtain, and replacement fingers could only be obtained from the original manufacturer, at high cost, and with long lead times, which led to replacement fingers not always being available when needed, affecting the production of the machine.

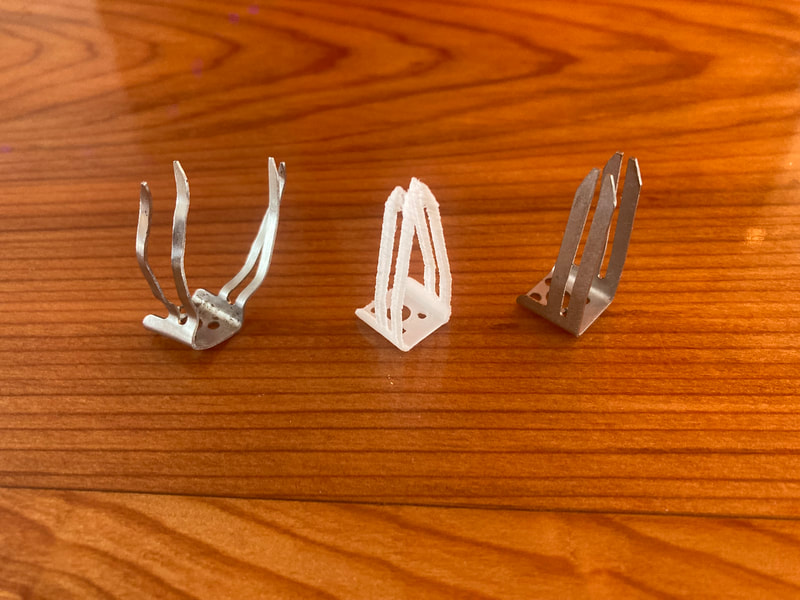

Millson Design Solutions scanned and reverse engineered the fingers, then 3D printed a set so they could be tested for fit and function. Once the fit was confirmed Millson Design Solutions sourced a Canadian Manufacturer who was able to fabricate the parts for less than a third of the cost the operator had been paying and with the ability to deliver them in less than a week.

Millson Design Solutions scanned and reverse engineered the fingers, then 3D printed a set so they could be tested for fit and function. Once the fit was confirmed Millson Design Solutions sourced a Canadian Manufacturer who was able to fabricate the parts for less than a third of the cost the operator had been paying and with the ability to deliver them in less than a week.