Truck Box Safety Pin Bore Repair

A mining contractor, working on a remote developmental mine site, damaged the safety pin bore on a rock truck box. This meant the box could not be pinned in the raised position, which was required for regular maintenance, creating a safety concern.

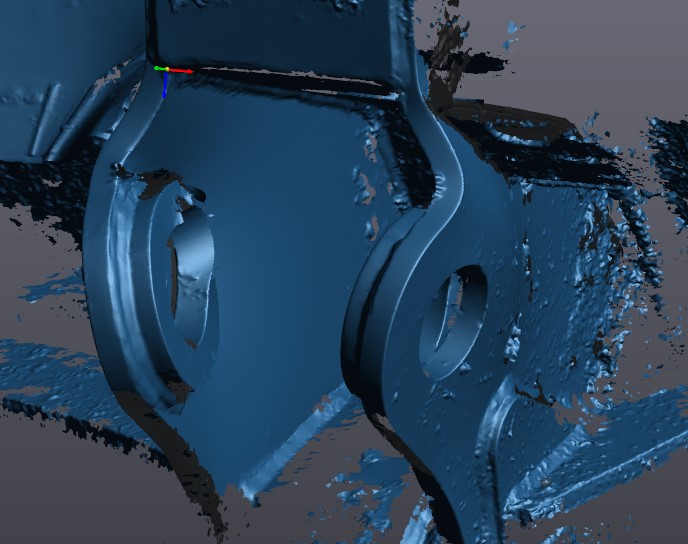

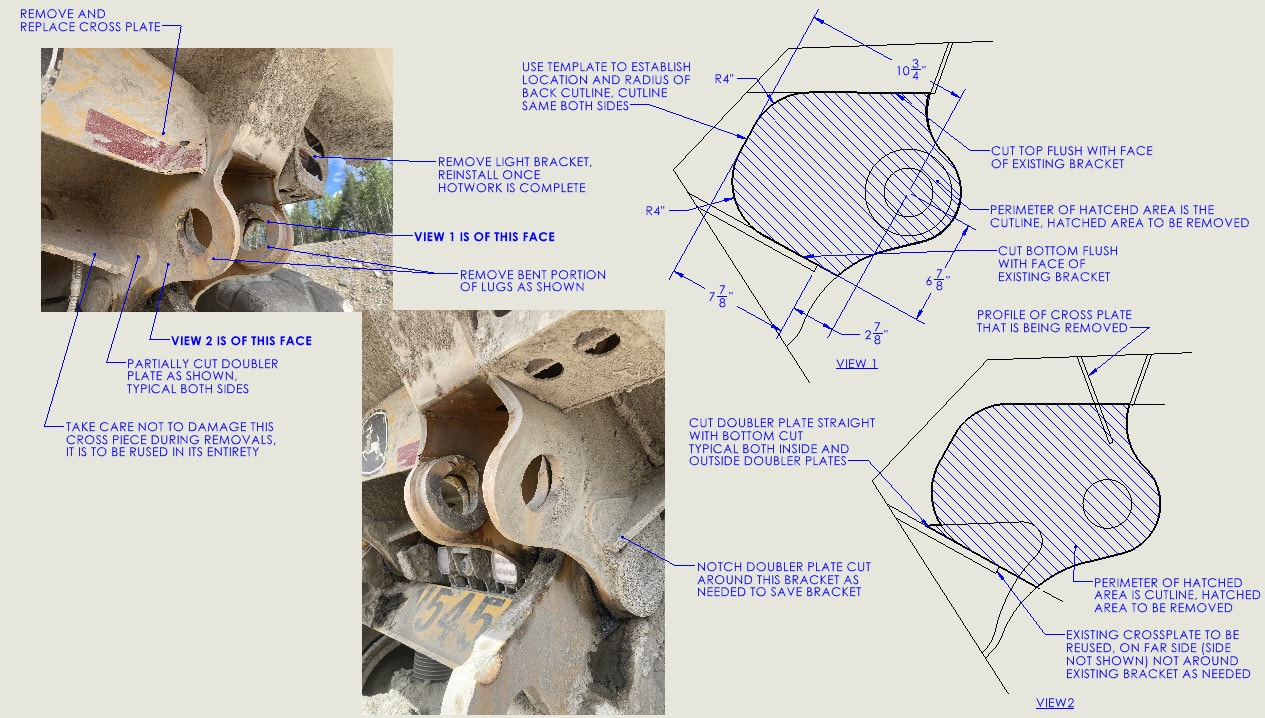

Millson Design Solutions was brought onsite and in less than a half hour scanned both the bores on the damaged box, as well as an undamaged set on another truck for refence. From these scans Millson Design Solutions created a repair package including guidance on how the damaged components were to be cut out and removed and details on how the replacement components were to be fitted and welded in.

The precision that can be obtained through the 3D scanning process, allowed for all replacement components to be CNC cut using files provided by Millson Design Solutions, and weld prepped offsite, reducing the amount of work that needed to be completed in the field.

Millson Design Solutions was brought onsite and in less than a half hour scanned both the bores on the damaged box, as well as an undamaged set on another truck for refence. From these scans Millson Design Solutions created a repair package including guidance on how the damaged components were to be cut out and removed and details on how the replacement components were to be fitted and welded in.

The precision that can be obtained through the 3D scanning process, allowed for all replacement components to be CNC cut using files provided by Millson Design Solutions, and weld prepped offsite, reducing the amount of work that needed to be completed in the field.