|

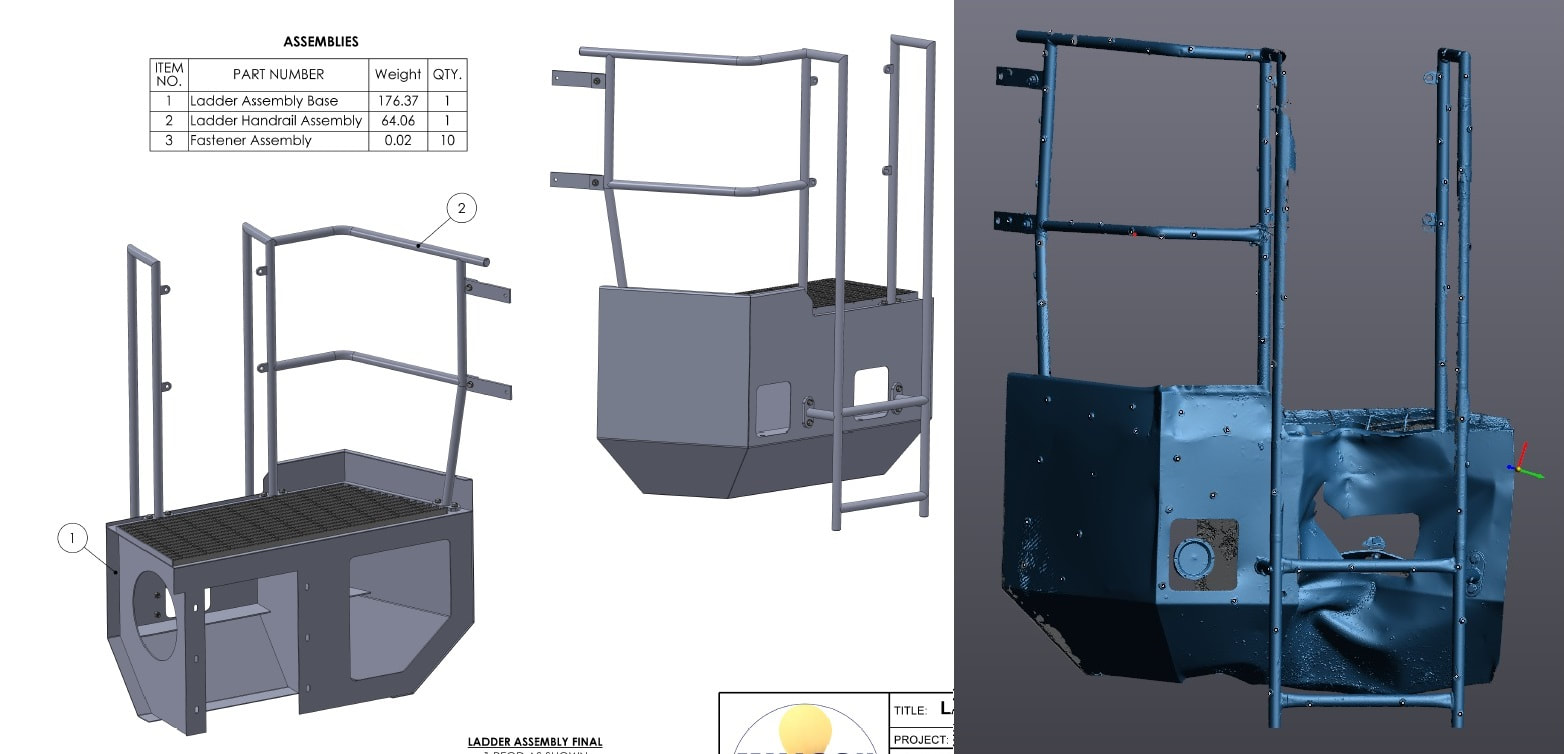

Another benefit of a handheld scanner is the size of the object to be scanned is almost unlimited and Millson Design Solutions has scanned objects smaller than an inch to equipment larger than a 200 ton rock truck box. The versatility of the scanner also means scans can be completed in enclosed and hard to reach places. Millson Design Solutions regularly scans equipment in mills with only a minimal amount of guarding removed, decreasing the amount of work and equipment downtime necessary to complete the scan.

|

Millson Design Solutions 3D scanning technology is best described as detailed, accurate and fast. Millson Design Solution handheld scanner is extremely portable allowing the scans to be completed almost everywhere, including from scaffolding or ladders, and in dusty and wet industrial environments. The scanner can run off both a battery or a small generator ensuring even large scans can be completed in remote areas with no onsite facilities.

|

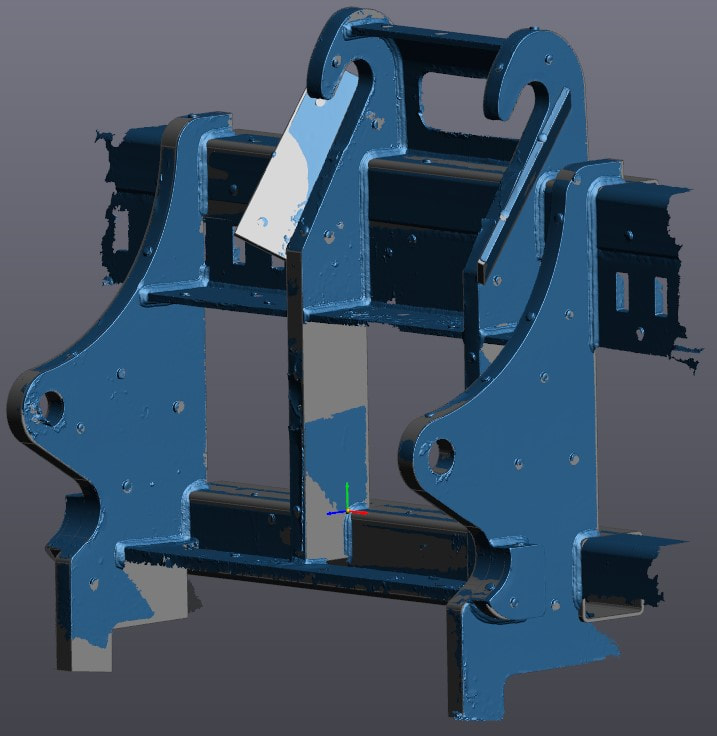

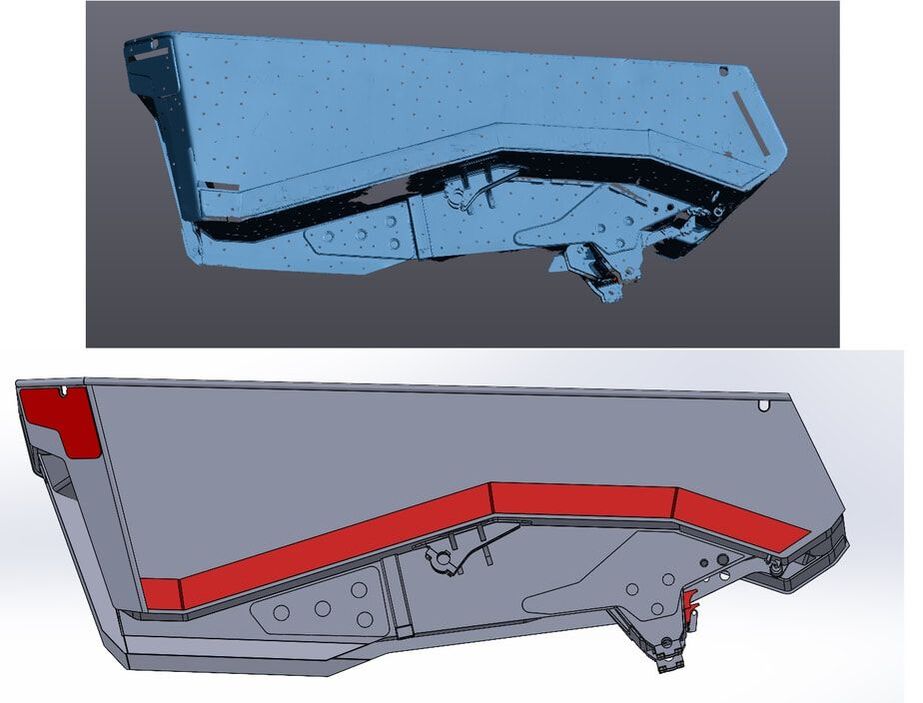

Once the scans are completed Millson Design Solutions has all the software needed to take the scan, recreate it in CAD and produce detailed fabrication drawings and cut files. These CAD can then be overlayed onto the scan to verify accuracy

The uses of this technology are almost endless and can be used for reverse engineering, surveying existing areas to ensure newly designed equipment will properly fit existing infrastructure, and for quality control to ensure that fabricated objects match their original design drawings. By using the scanner for quality control Millson Design Solutions can help mill and mine operators ensure items will fit before they arrive onsite, decreasing the chance for issues to arise during a shutdown installation. |